Efficient processes

by individual concepts:

Total productive maintenance (TPM)

The total productive Maintenance (TPM) describes an approach to get the maximum effectiveness of the equipment within a company. Total productive maintenance aims the improvement of the current condition and performance of the equipment by simple and repeated maintenance work.

Pearl necklace

The concept of the Pearl necklace is based on a predetermined order of the assembly and determines the exact oder of assembly steps. Prerequisite for the production`s synchronous delivery based an predefined string of pearls is the ability to a “one-time Piece-flow” assembly. The Assembly will be done in a predetermined way.

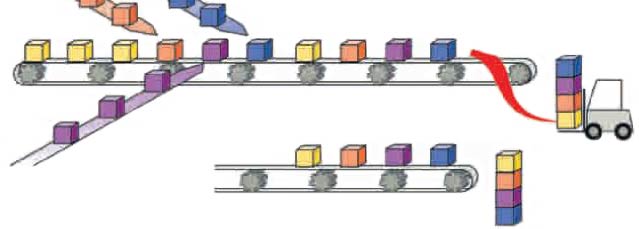

One-Piece-Flow

One-piece-flow represents the continuous product or material flow bettween individual processing / assembly stations. Care must be taken to ensure that the workpieces will be processed one by one without any overtaking maneuvers.

First in first out (FiFo)

With the first in first out principle (short FiFo) the material or goods that have been delivered first, will be consumed first.

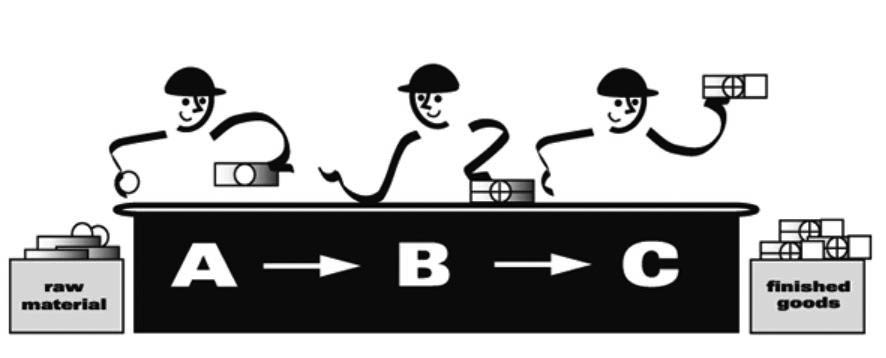

Just-in Time

Just-in Time (JIT) defines a production – and manufactoring orientated concept. The necessary components will be deliverd directly into the process at the moment where they are needed.

The traditional buffer and intermediate storage can be omitted

Shopfloormanagement

“Shopfloor management” is a management philosophy, with which managers at the point of origin secure the company`s core processes by employing persuasive key data and ensuring adherence to standards. When irregularities occur, the managers support their employees in looking for a suitable solution, while ensuring that solutions lead to standards. Their task is to set an example as regards company values and to challenge and support their employees in order to establish a working culture that aims at common objectives.